Page 2 - Thermal Spray - Hi-Tech Compressor

P. 2

WHAT IS THERMAL WHY THERMAL

SPRAY? SPRAY?

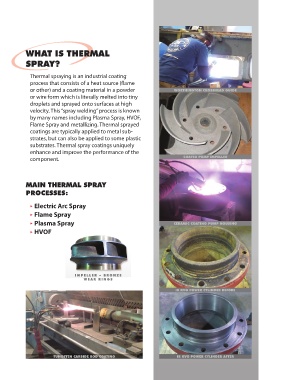

Thermal spraying is an industrial coating Thermal spraying repairs worn metal-

process that consists of a heat source ( ame lic items. Unlike most repairs, thermal

or other) and a coating material in a powder WORTHINGTON CROSSHEAD GUIDE spraying is not a “band-aid” x. It will

or wire form which is literally melted into tiny restore your part back to OEM speci -

droplets and sprayed onto surfaces at high cations or better!

velocity. This “spray welding” process is known

by many names including Plasma Spray, HVOF, ► Improve Performance

Flame Spray and metallizing. Thermal sprayed With the ability to bond and coat stronger

coatings are typically applied to metal sub- and more durable materials to your worn

strates, but can also be applied to some plastic parts, thermal spraying can increase the

substrates. Thermal spray coatings uniquely life and performance of your parts.

enhance and improve the performance of the ► Reduce Costs

component. COATED PUMP IMPELLER With the high replacement costs of most

parts, thermal spraying often is less than

half the cost of replacement.

► Reduce Downtime

MAIN THERMAL SPRAY We have turnaround times as low as 24 hrs.

PROCESSES:

Electric Arc Spray Thermal spraying is an e ective

►

Flame Spray alternative to several surface modi -

► cations including: nickel and chrome

Plasma Spray

► CERAMIC COATING PUMP HOUSING plating, nitride or heat treat pro- Metal Arc Spray on 36” Bearing Washer

HVOF cesses, anodizing and weld overlay.

►

The broad choice of materials give

you design exibility to solve speci c

performance problems.

I M P E L L E R – B R O N Z

I M P E L L E R – B R O N Z E E

W E A R R I N G S

IR KVG POWER CYLINDER BEFORE

B E F O R E

B R O N Z E R I D E R B A N D S

TUNGSTEN CARBIDE ROD COATING IR KVG POWER CYLINDER AFTER A F T E R

H i - Te c h C o m p r e s s o r s & P u m p P r o d u c t s , I n c . w w w . h i - t e c h c o m p r e s s o r. c o m